Unlike the crank it up mantra typically held in the organic courtroom, inorganic structures can be made at temperatures that are often lower than conventional thermal approaches. The debate (which I will discuss in an upcoming post) in the organic field is that everything can and will be answered as a thermal phenomenon. A recent article shares some of the views within the community.

The inorganic and catalysts community can contribute to the hand-waving. In many cases, we talk about several potential phases and nucleation events that drive the production of a desired compound or crystal. Not to complicate the story, but depending on the source of energy applied, different elements can dissipate the energy absorbed at temperatures greater (“superheating”) than the temperature of the surrounding environment. This has been acknowledged in microwave reactions to form a variety of inorganic crystals….and born out in specific structures that have been made utilizing microwave irradiation where the conventional thermal process failed.

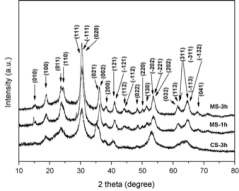

A recent publication utilizing a solvothermal microwave synthesis for the formation of ZnWO4 illustrates an improved crystalline wolframite structure without impurities. This is important since it is reflected in improved photocatalytic activity. Metal tungstates as a class have been utilized as scintillating medium and electro-optic applications. Conventional ZnWO4 crystals were compared with microwave-based crystals formed with 1 h and 3 h time points. The MS- 3h crystals (XRD patterns below) were identified as the most crystalline, with the best activity. In terms of the preparation, zinc sulfate and ammonium paratungstate were placed in a Telfon microwave vessel with ethylene glycol. The pH was adjusted to 9 using 4 M NaOH. Once the microwave vessel was closed, the reaction was brought to 160C for 1 h or 3 h, cooled and washed with DI water. Following a brief drying period at 80C, the crystals were analyzed (~10 nM nanocrystals). The intensity of the XRD increased and full width at half maximum decreased, indicating the enhancement of crystallinity and crystal size. Examining the literature, this is a general trend in using microwave methods compared with conventional heating….a more uniform and better crystal formation, largely due to a more uniform heating of the contents in place of allowing the heating the vessel and waiting for the contents to come to temperature.

2 Trackbacks / Pingbacks for this entry:

[…] I briefly alluded to this in a previous post, it bears some splash on how funny technology and science discussions go. If you want to have fun […]

[…] because conventional approaches do not provide volumetric heating. Unlike the the last approach (MW solvothermal) at 160C for 1 and 3 h, this group reports studies at multiple temperatures and ultimately settling […]